The intersection of wastewater treatment and renewable energy generation has long been a focal point for environmental engineers and sustainability experts. In recent years, a groundbreaking innovation has emerged from this convergence: microbial fuel cells (MFCs) that simultaneously treat sewage while generating electricity. This dual-purpose technology represents a paradigm shift in how we approach both waste management and clean energy production.

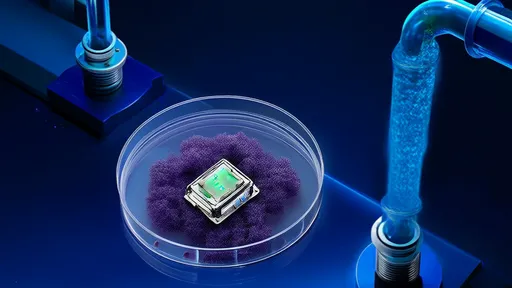

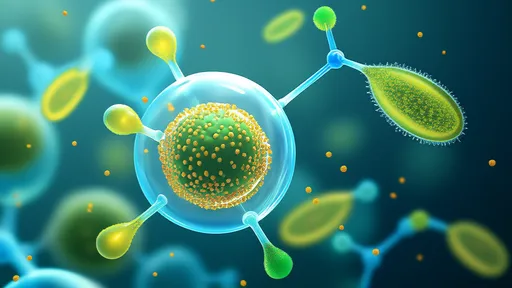

At its core, the microbial battery system harnesses the metabolic activity of electroactive bacteria to break down organic matter in wastewater. These remarkable microorganisms naturally release electrons as they digest pollutants, creating a flow of electrical current through specially designed electrodes. Unlike conventional treatment plants that consume significant energy, these bioelectrochemical systems actually produce power while achieving comparable or better purification results.

The science behind this technology reveals nature's elegant efficiency. When wastewater flows through the MFC's anode chamber, bacteria form a biofilm on the electrode surface. As they metabolize organic compounds, the microbes transfer electrons to the anode. These electrons then travel through an external circuit to the cathode, creating usable electricity. Meanwhile, protons migrate through a membrane to complete the circuit, combining with oxygen at the cathode to form clean water as the only byproduct.

Recent field trials have demonstrated the practical viability of microbial battery systems. A pilot plant in Singapore achieved 85% organic removal efficiency while generating 0.5 kWh per cubic meter of treated wastewater - enough to power the plant's auxiliary systems with surplus energy remaining. Perhaps more impressively, the system operated continuously for eighteen months without significant performance degradation, proving its reliability under real-world conditions.

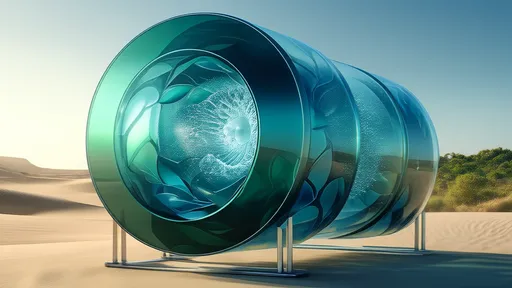

What sets microbial fuel cells apart from other green technologies is their inherent scalability. Municipal treatment facilities can implement large-scale MFC arrays, while smaller units prove ideal for remote communities, industrial sites, or even individual buildings. This flexibility addresses one of wastewater treatment's greatest challenges: extending effective sanitation to areas lacking infrastructure. The technology's modular nature allows for gradual expansion as needs grow, making it particularly valuable for developing regions.

The environmental benefits extend beyond clean water and renewable electricity. Traditional wastewater plants emit substantial greenhouse gases, particularly methane and nitrous oxide. Microbial battery systems dramatically reduce these emissions by converting organic matter directly to electricity rather than allowing anaerobic decomposition. Early lifecycle assessments suggest MFC-based treatment could cut the carbon footprint of wastewater processing by 60-80% compared to conventional methods.

Economic analyses reveal another compelling advantage. While initial capital costs remain higher than traditional systems, the long-term economics favor microbial batteries. Energy production offsets operating expenses, and the systems require less maintenance than mechanical treatment plants. As the technology matures and production scales, experts anticipate installation costs will decrease significantly within the next decade.

Implementation challenges persist but appear surmountable. Electrode materials currently account for much of the system's expense, prompting research into cheaper, more efficient alternatives. Carbon-based nanomaterials and conductive polymers show particular promise. Another focus area involves optimizing bacterial communities to enhance both treatment efficiency and power output. Some research teams are exploring genetically modified strains that could double current energy yields.

The potential applications continue to expand as the technology evolves. Forward-looking projects are testing MFCs for treating agricultural runoff, food processing waste, and even landfill leachate - each application producing clean water while generating electricity. In coastal areas, researchers are developing saline-tolerant systems that could revolutionize marine wastewater treatment. The versatility of microbial electrochemistry suggests we've only begun tapping its possibilities.

Policy makers are taking notice of this transformative technology. Several countries have included microbial fuel cells in their clean technology roadmaps, with funding initiatives supporting both research and demonstration projects. Regulatory frameworks are adapting to accommodate these systems, recognizing their potential to help nations meet both sanitation and renewable energy targets simultaneously.

The societal implications could be profound. Nearly two billion people lack access to proper sanitation worldwide, while energy poverty affects even more. Microbial battery systems offer a solution that addresses both issues in tandem, particularly in off-grid areas. The technology's simplicity - requiring no sophisticated machinery or extensive operator training - makes it especially suitable for deployment in developing nations.

As urbanization intensifies and climate change accelerates, the need for sustainable infrastructure solutions becomes ever more urgent. Microbial fuel cells represent more than incremental improvement; they offer a fundamental reimagining of wastewater treatment's role in the circular economy. What was once considered merely waste to be disposed of becomes a valuable resource, processed in a system that gives back more than it takes.

The coming decade will likely determine whether this technology achieves widespread adoption or remains a niche solution. Current indicators suggest we may be witnessing the early stages of a quiet revolution in environmental engineering. As research progresses and pilot projects multiply, microbial batteries could well become standard equipment in tomorrow's wastewater treatment plants - turning our sewage problems into power solutions.

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025

By /Jul 10, 2025